John,

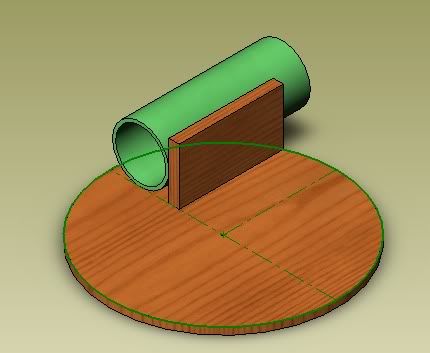

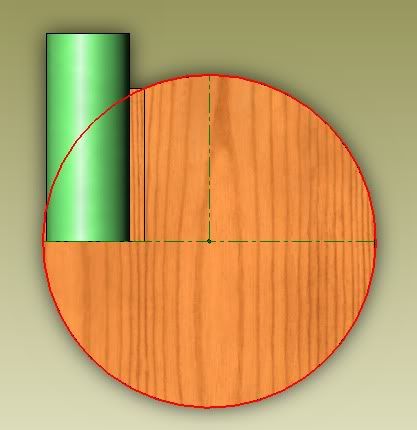

I had some 1/2" acrylic from an old display case that was used for the gate body. The holes were bored 1/16 over for the SR 35 PVC which is held in with clear silicon. 1/4-20 holes were drilled and taped to hold the halves together. The gate is 1/8 lexan. I bolted the lexan between the 2 halves and bored the holes through all 3 pcs at once to maintain perfect alignment.

Don Z.

I had some 1/2" acrylic from an old display case that was used for the gate body. The holes were bored 1/16 over for the SR 35 PVC which is held in with clear silicon. 1/4-20 holes were drilled and taped to hold the halves together. The gate is 1/8 lexan. I bolted the lexan between the 2 halves and bored the holes through all 3 pcs at once to maintain perfect alignment.

Don Z.