In the photo it is flush. I did another experiment with a stub that projected about 1.5" or so down, seemed to make no difference one way or another.

- Welcome to J. Phil Thien's Projects.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Pages1

#1

Thien Cyclone Separator Lid Discussion / Re: 5 gallon can seperator issues

September 19, 2008, 06:43:29 AM #2

Thien Cyclone Separator Lid Discussion / Re: 5 gallon can seperator issues

September 18, 2008, 07:48:03 AM

Pretty sure there are no leaks.

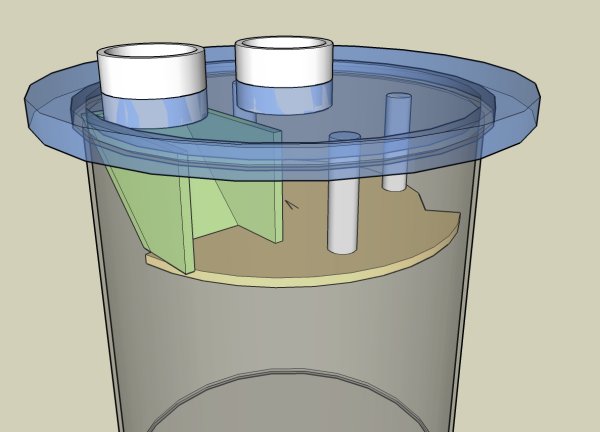

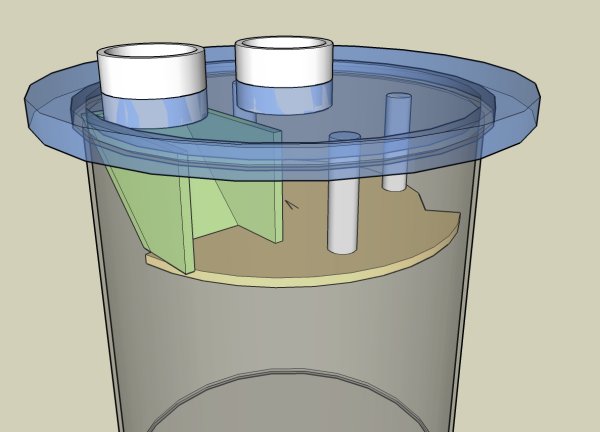

The pictures above show the first pass, after this I modified it by moving the inlet ramp so material could pass by as well as moving the baffle to what I think is the "original; design" position, you can see the outline of the baffle in pencil in the picture.

Based upon my not very scientific experiment the only difference I could see was that the lid assembly would retain some of the debris coming in (because it's a ramp, not a pipe).

I will try the inlet extension to see if it improves. Again, even as is this design works exceptionally better than the dust deputy on a 5 gallon bucket

PMB http://benchmark.20m.com

The pictures above show the first pass, after this I modified it by moving the inlet ramp so material could pass by as well as moving the baffle to what I think is the "original; design" position, you can see the outline of the baffle in pencil in the picture.

Based upon my not very scientific experiment the only difference I could see was that the lid assembly would retain some of the debris coming in (because it's a ramp, not a pipe).

I will try the inlet extension to see if it improves. Again, even as is this design works exceptionally better than the dust deputy on a 5 gallon bucket

PMB http://benchmark.20m.com

#3

Thien Cyclone Separator Lid Discussion / 5 gallon can seperator issues

September 15, 2008, 08:02:27 AM

I am trying to adapt this separator design to a 5 gallon can and I am wondering if it can be optimized a little for better performance.

First, I want to qualify that by saying that even in it?s un-optimized state it works over 100% better than a similar dust deputy setup and catches well over 90% of the stuff coming in and has no discernable scrubbing action.

The problem that I am having is that I am getting a little blow by into the shop vac. I highly suspect that there isn?t much further that can be done and that the small size of the can itself is the primary bad actor here.

http://benchmark.20m.com/images/PTv1.skp

I messed around with a few other little tweaks like adding a pipe sutb inside, adjusting the baffle plate a little, moving the inlet ramp a little, it didn't seem to make any noticable difference.

PMB

http://benchmark.20m.com

First, I want to qualify that by saying that even in it?s un-optimized state it works over 100% better than a similar dust deputy setup and catches well over 90% of the stuff coming in and has no discernable scrubbing action.

The problem that I am having is that I am getting a little blow by into the shop vac. I highly suspect that there isn?t much further that can be done and that the small size of the can itself is the primary bad actor here.

http://benchmark.20m.com/images/PTv1.skp

I messed around with a few other little tweaks like adding a pipe sutb inside, adjusting the baffle plate a little, moving the inlet ramp a little, it didn't seem to make any noticable difference.

PMB

http://benchmark.20m.com

Pages1