Hi guys! I am designing a a separator using Fusion 360, and I am planning to cut some parts on CNC and 3d print some others. This allows a bit of flexibility without much hustle.

I have a couple of questions, hope you can help me.

1) In terms on the general geometry of the separator, does it matter if it's a spiral or a circle? If a spiral is better, does it matter what kinda of spiral it is?

2) What term do u use to refer to the air outlet of the sepator? (EG: I am talking about the pipe that's fixed to the top lid).

3) Is there any kinda of guide or calculations that are good to follow in terms of the location of the hole on the bottom plate, where it should start and finish?

4) is there any guidelines about using ramps or vanes?

Thanks in advance!

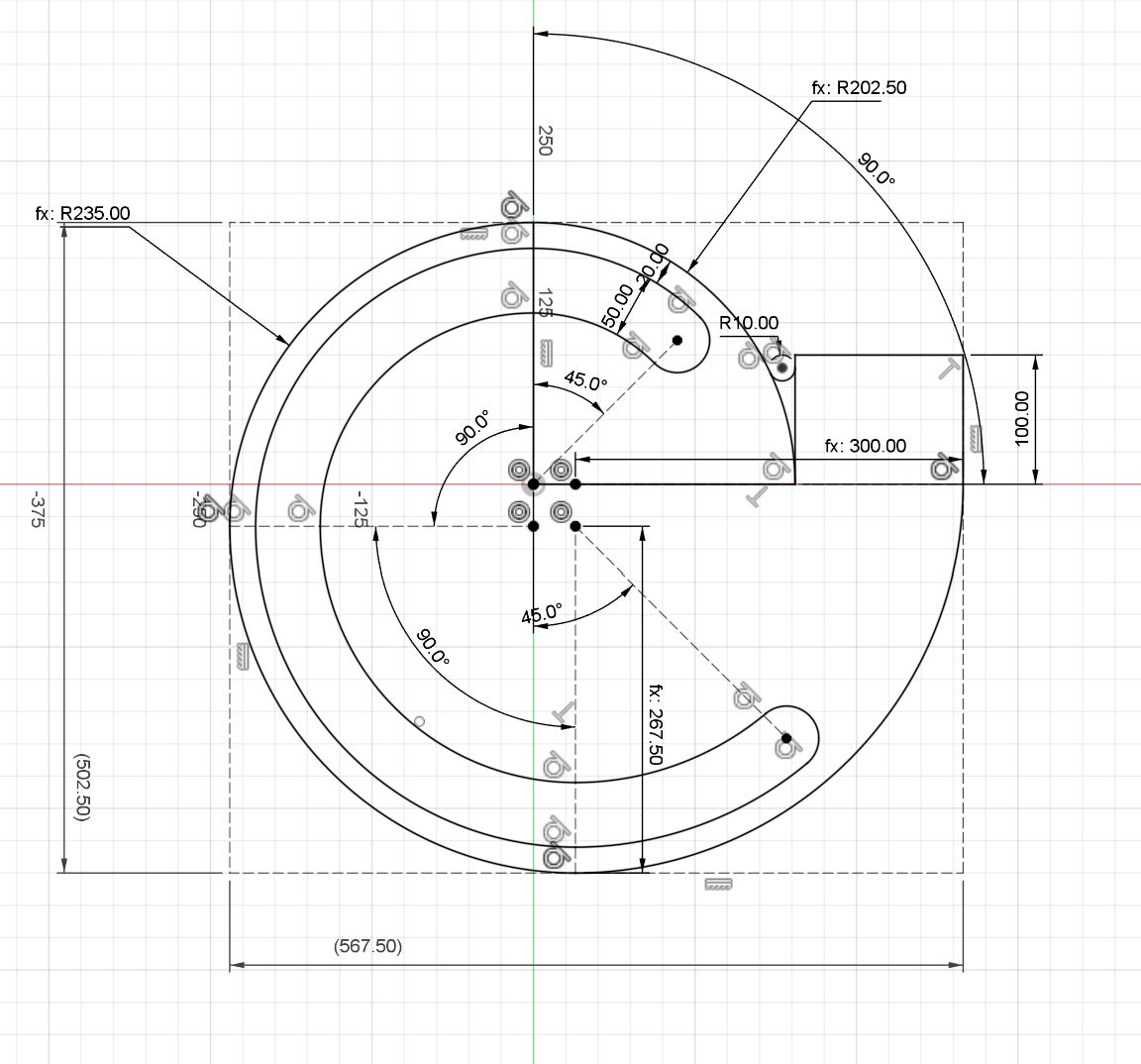

This is the shape that I am working with for now. I think this is called a quarter arc spiral, is simple 4 tangent arcs that are slighltly bigger by a fixed step. Fusion is kinda not good for sketching spirals so i have to work around it.

Here are some images of my general idea. I am still sketching the ideas.

I have a couple of questions, hope you can help me.

1) In terms on the general geometry of the separator, does it matter if it's a spiral or a circle? If a spiral is better, does it matter what kinda of spiral it is?

2) What term do u use to refer to the air outlet of the sepator? (EG: I am talking about the pipe that's fixed to the top lid).

3) Is there any kinda of guide or calculations that are good to follow in terms of the location of the hole on the bottom plate, where it should start and finish?

4) is there any guidelines about using ramps or vanes?

Thanks in advance!

This is the shape that I am working with for now. I think this is called a quarter arc spiral, is simple 4 tangent arcs that are slighltly bigger by a fixed step. Fusion is kinda not good for sketching spirals so i have to work around it.

Here are some images of my general idea. I am still sketching the ideas.